Balanced Laminate Define

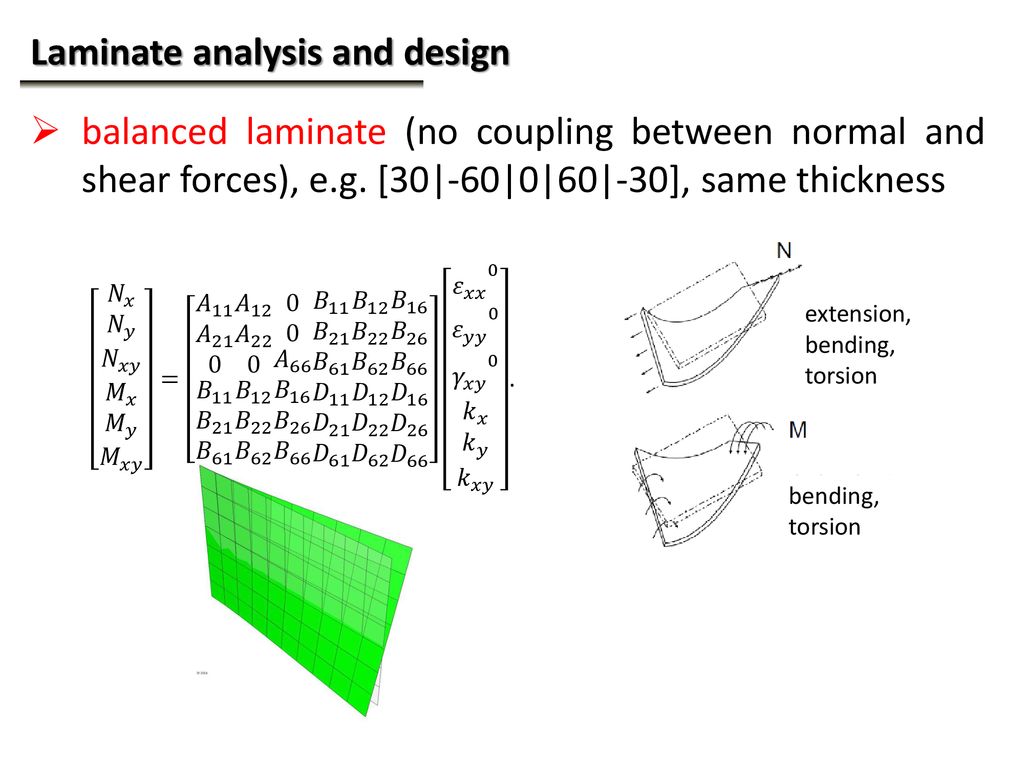

Composite laminates may be regarded as a type of plate or thin shell structure and as such their stiffness properties may be found by integration of in plane stress in the direction normal to the laminates surface.

Balanced laminate define. Laminate definition is to roll or compress into a thin plate. Balanced laminate a composite laminate in which all laminate at angles other than 0 and 90 occur only in pairs not necessarily adjacent and are symmetrical around the centerline. If the laminate is not balanced and symmetric macro warpage will certainly occur during cool down. Gardner business media acquires netcomposites media assets.

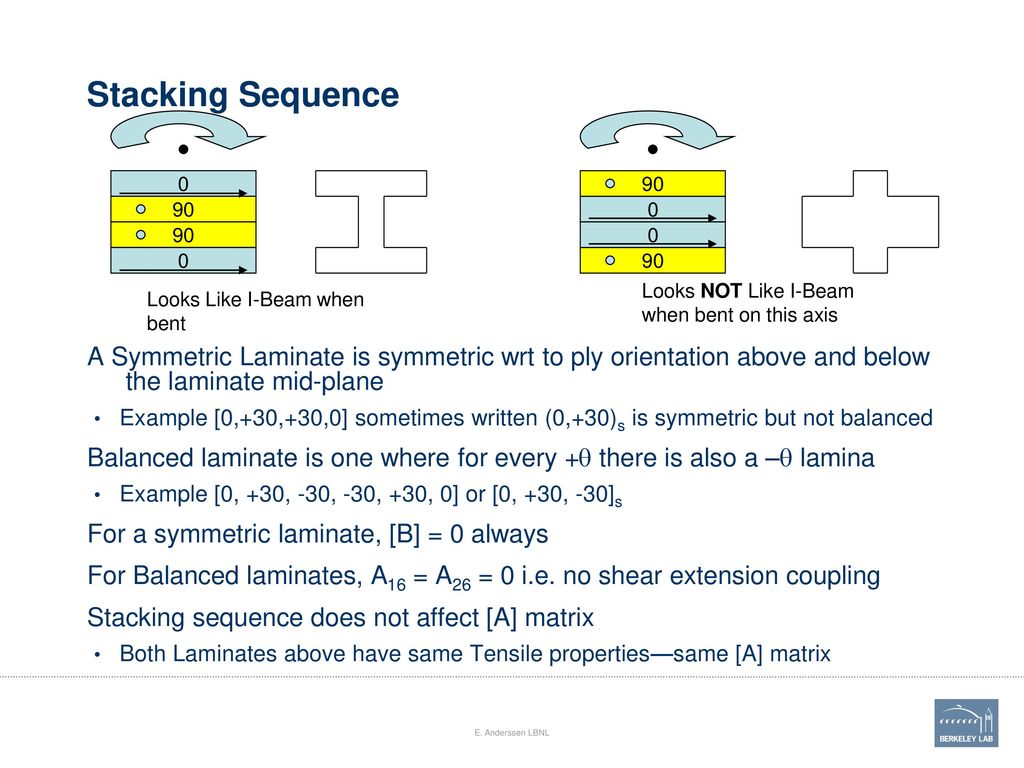

Melamine paper is thermally bonded to particleboard or mdf panels. A composite laminate in which all laminate at angles other than 0o and 90o occur only in pairs not necessarily adjacent and are symmetrical around the centerline. Balanced laminates a laminate is balanced when it consists of pairs of layers of the same thickness and material where the angles of the plies are θand θ. Hence a laminate with a stacking sequence 0 90 45 45 45 45 90 0 which is written 0 90 45 s is both balanced and symmetric.

Examples of balanced laminates are. Each complete laminate is enclosed in a set of brackets symmetric laminates with an even number of plies are represented by listing all plies on one side of the mid plane enclosed in brackets followed by the subscript s. The instrument called the. An example of a balanced laminate is 0 45 45 90 45 45 0 whereas an unbalanced laminate would be 0 45.

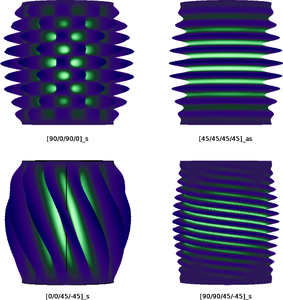

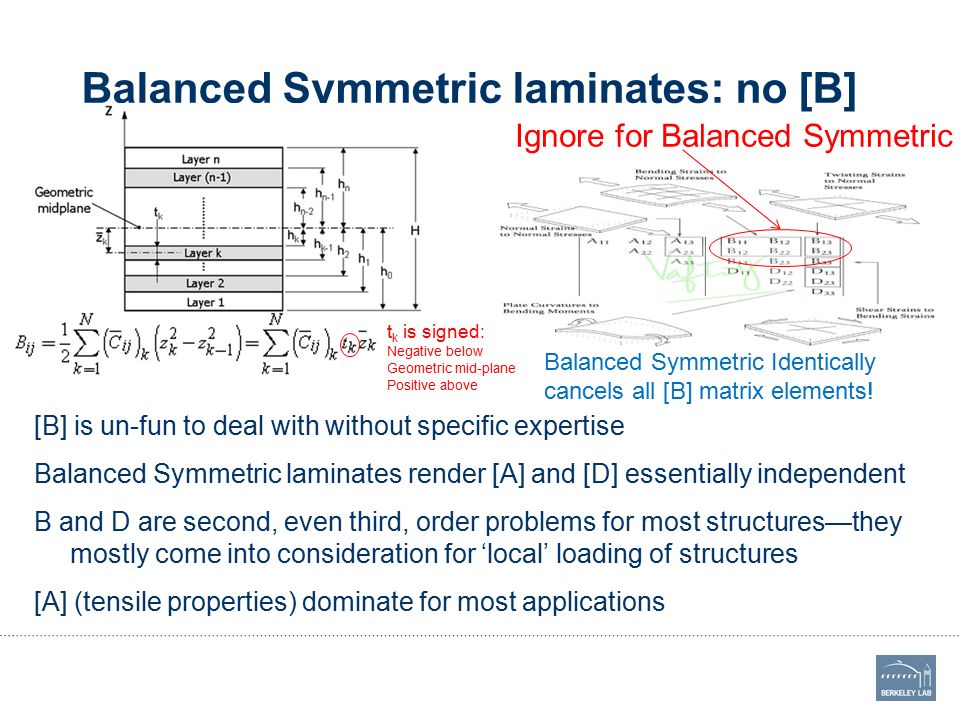

Barcol hardness a hardness value obtained by measuring the resistance to penetration of a sharp steel point under a spring load. Melamine or tfm thermally fused melamine or lpl low pressure laminate. A balanced laminate is one that for every θ ply in the lay up there is an equivalent θ ply in the lay up. Balanced symmetric laminates have a simplicity of response.

Laminate orientation code repeating groups of plies within a laminate can be placed in parentheses. Firstly a perfunctory definition is in order regarding a balanced laminate. This is produced in higher volumes than hpl. A designer will need to ensure that for every α ply there is a α ply with the same material and thickness somewhere within stacking sequence irrespective of location.

Tfm must be applied to the front and back of the panel to keep the panel balanced. In contrast an unbalanced asymmetric laminate will in general shear bend and twist under a simple axial loading.

/Quasi%20isotropic%20carbon%20fiber%20manufactured%20in%20cny.png)